You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bty34 TJ Build

- Thread starter bty34

- Start date

- Featured

I think I need to tie my sliders into my frame. I’ve dented my tub pretty badly in front of the passenger door from body drops!

It is tempting to do boat sides instead, but it seems like a slippery slope.

Removed some of the front section of torque box. The floor was a little thin where they overlapped and opened up when I went at it with the cup brush. I debated about using a sheet of 18ga to patch it, but Im going to order a floor pan and do a bigger area.

I'm becoming less and less of a fan of bedliner. Raptor doesn't seem as bad as herculiner, but the coating seems to stay together well enough when it debonds from the metal that it's hard to tell it's been compromised.

Copied Florpro and welded up my trailer jack. Worked pretty well to get the rollbar out of the way. Had to weld nuts to 3 of the torx bolts. I was happy none of them spun or snapped.

Wasn't too bad under the b pillar. I'm thinking I'll go just outside the old seam all the way to the outside rather than splicing in a strip.

Wasn't too bad under the b pillar. I'm thinking I'll go just outside the old seam all the way to the outside rather than splicing in a strip.

When I installed the Atlas, I settled on the 15° clocking position, partially because of how high it let me shove the transmission. I wasn't able to fully utilize that as the Atlas hung slightly lower and it also limited the allowable height for the center of the stiffener.

Looking at how the skid is holding up, I need to make some changes.

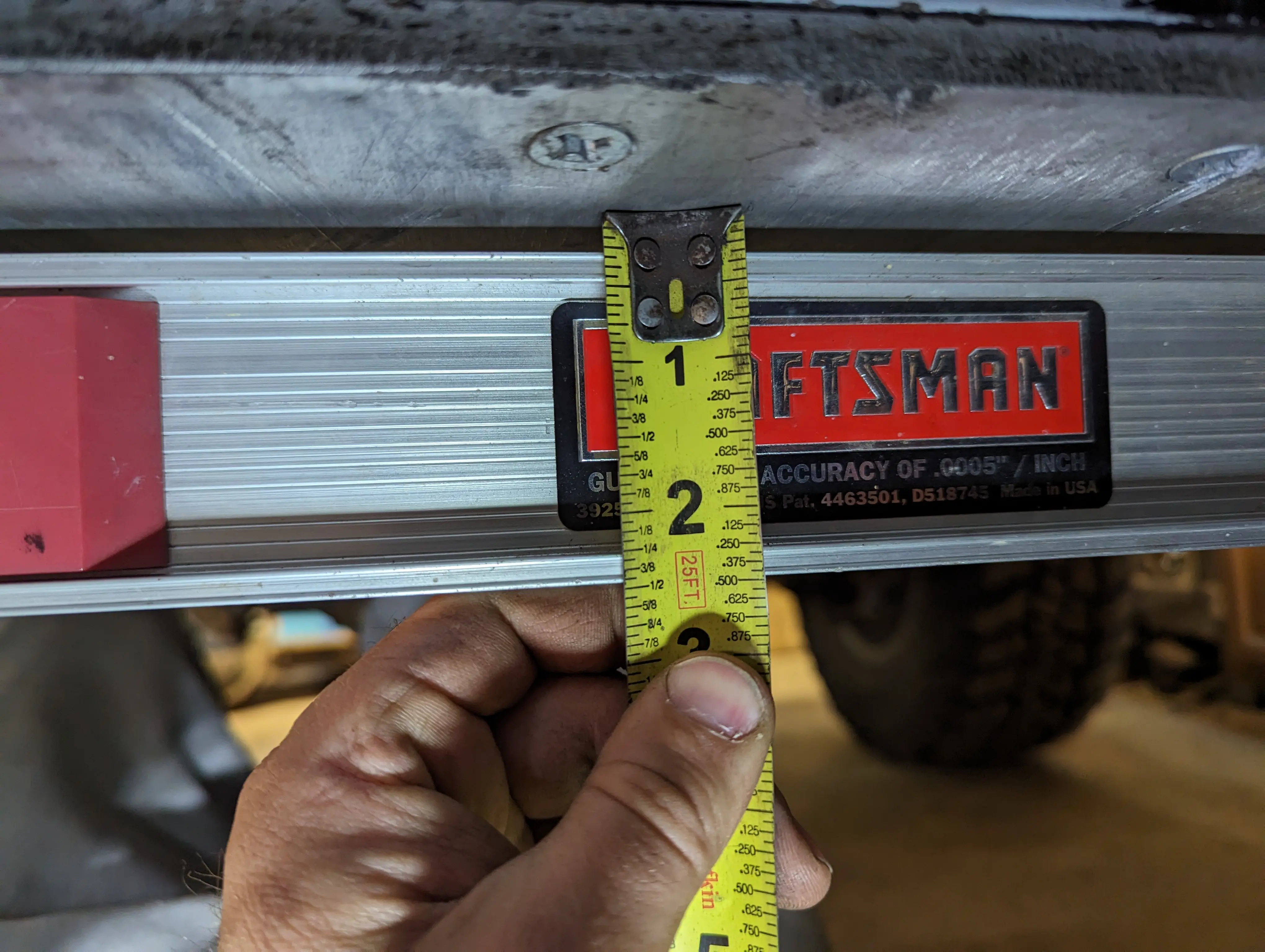

It's bent about 1/4". I think it bent enough to contact the corssmember and then the added support was enough. I knew the rear brace was on the light side, but I didn't remember anything more than dragging on the skid.

Looking at how the skid is holding up, I need to make some changes.

It's bent about 1/4". I think it bent enough to contact the corssmember and then the added support was enough. I knew the rear brace was on the light side, but I didn't remember anything more than dragging on the skid.

Here's what I'm thinking. The 3/8" 6061 is pretty strong (2400 pounds) but deflects 2.4" with that load. It should spring back though on its own.

With the steel brace added, it adds some strength, but also permanently deforms at much lower deflection. I need to pull the rear brace to confirm, but I'm thinking it's bent and preventing the aluminum from returning to flat.

My current set is roughly in the red. The aluminum and rear angle will permanently deform around 600 lbs. and shortly after contact the center cross member which adds another 1000 lbs of strength. Since that isn't bent, I probably only had 1/3 of the Jeep resting on the skid.

The yellow boxes are close to what I remember the Savvy UA being composed of. All together 5k pounds for the Savvy seems reasonable and a good target.

It really helps the strength of the Savvy arrangement to have the cross member bolted to the skid and the isolation between it and the transmission mount. Since I have the bushings at the frame, I think I need to keep the 1/4" gap I have currently.

Last edited:

Modified the rear brace for the skid with another piece of angle I had laying around. Also added 1/2" of drop in the center. The aluminum should accommodate that without remaking the plate. Should by some time for a more permanent solution.

Finally got the torque box off and cut out the front floor pan. Since I had the full replacement panel, I put the cuts where I thought it would match up easiest rather than just doing the rust areas.

Finally got the torque box off and cut out the front floor pan. Since I had the full replacement panel, I put the cuts where I thought it would match up easiest rather than just doing the rust areas.