You are using an out of date browser. It may not display this or other websites correctly.

You should upgrade or use an alternative browser.

You should upgrade or use an alternative browser.

Bty34 TJ Build

- Thread starter bty34

- Start date

- Featured

Must be for looks, sure aren't worth the weight or poor road manners.

Straightened the tie rod again. It's .120 wall Dom sleeved with a solid bar of 4340. I'm wondering if I should have gone with normalized 4340 over the annealed. It would put it closer to 3000 lbs before permanent deformation rather than the ~1600 lbs currently. Next time Blaine does a run of tie rods he's supposed to put me on the list.

Straightened the tie rod again. It's .120 wall Dom sleeved with a solid bar of 4340. I'm wondering if I should have gone with normalized 4340 over the annealed. It would put it closer to 3000 lbs before permanent deformation rather than the ~1600 lbs currently. Next time Blaine does a run of tie rods he's supposed to put me on the list.

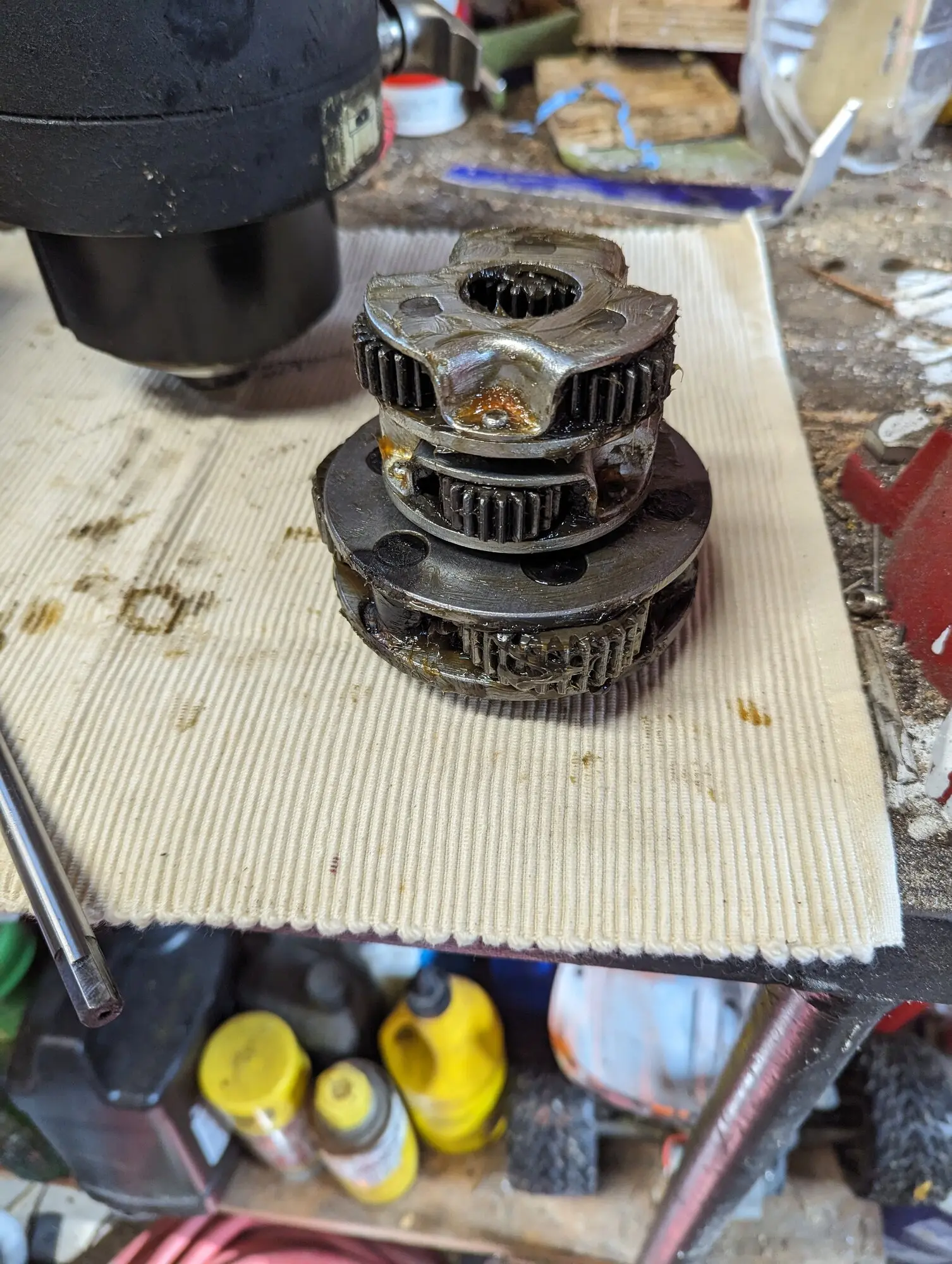

The freespool on my winch has gotten a little stiff. Pulled the gearcase off it to clean and regrease. Even had some help with the cleaning part. I think it feels quite a bit better even though the old grease didn't look that bad. Hopefully it's not all in my head.

Attachments

Ugh. Same here.The freespool on my winch has gotten a little stiff.

You had a great supervisor on site!

Jeffro06

Well-known member

Eat more Wheaties. 💪The freespool on my winch has gotten a little stiff. Pulled the gearcase off it to clean and regrease. Even had some help with the cleaning part. I think it feels quite a bit better even though the old grease didn't look that bad. Hopefully it's not all in my head.

I usually get myself in enough of a predicament that it ends up needing to be my wife or someone else that pulls the cable. Pretty soon the kids will be big enough so I shouldn't ever have to do it again. I should probably do the same thing to the used winch sitting on the shelf for the flatfender. First one used about half a tube of grease.

Got a little bit of rain each day, but overall the weather was pretty decent. Hit a bunch of blue trails and a handful of blacks. Managed to drop my tie rod on a rock on the last trail of the day. Adjusted the toe a little in the parking lot and made the 4hr ride home. The 4cyl took the trailer spot.

When I installed the rear axle, I had a hard time getting the vent line out from under the truss without kinking. I thought I might get away with the short "s" hose and connecting it to the stock 5/16" breather. It worked ok, but would occasionally (like 1/4 of the time) push oil out the vent. I finally committed to drilling a hole through the truss to switch it all to 3/8" hose. I didn't notice any oil residue on either 4 hr drive, so I'll call it a success for now.

The freespool on the winch was improved with the fresh grease, feels pretty similar to the new winch on the other Jeep.

I have a habit of losing the bolts that attach the engine to transfercase skids. I copied the bolt pattern from the Savvy setup, but wonder if the engine skid is flexing too much with most of the sides cut off. Might pull the bolts before spring and clean them up and add loctite. I haven't had an issue with the same bolts on the rear of the main skid that hold the stiffener.

It also needs a bath. I've only gotten around to one so far.

The freespool on the winch was improved with the fresh grease, feels pretty similar to the new winch on the other Jeep.

I have a habit of losing the bolts that attach the engine to transfercase skids. I copied the bolt pattern from the Savvy setup, but wonder if the engine skid is flexing too much with most of the sides cut off. Might pull the bolts before spring and clean them up and add loctite. I haven't had an issue with the same bolts on the rear of the main skid that hold the stiffener.

It also needs a bath. I've only gotten around to one so far.

Last edited:

Dropped the tank on the 4cyl to increase the capacity a little on the 15 gallon tank.

The gas tank skid was pretty well built, but decided to switch to a late model skid to lose some weight and for the slightly smaller footprint. Dropped 40-45 lbs.

I think the late model skid should hold up ok. I'd be more concerned if the bottom of the old skid looked like mine.

The gas tank skid was pretty well built, but decided to switch to a late model skid to lose some weight and for the slightly smaller footprint. Dropped 40-45 lbs.

I think the late model skid should hold up ok. I'd be more concerned if the bottom of the old skid looked like mine.

Attachments

Last edited:

Starting to put together a plan for smaller rear brakes. Goal is to match the bias of Blaine's 17" kit, raise the calipers up out of the way. I'd also like to retain a parking brake and add some width to the rear axle once the calipers are less exposed.

Stock super duty rotors are 30mm thick. I had no luck finding a smaller caliper to fit my current rotors. After far too long looking at brake parts, I think a rotor from a 2000-2011 Cadillac limo could be modified to work. This gets be down to a 20mm rotor and the parking brake hat is only 5mm bigger. Down side is 8x6.5 and the hub register is too small.

20mm rotor will allow use of a rear caliper from a trailblazer, which is a single 48mm piston versus my current dual 44mm.

Stock super duty rotors are 30mm thick. I had no luck finding a smaller caliper to fit my current rotors. After far too long looking at brake parts, I think a rotor from a 2000-2011 Cadillac limo could be modified to work. This gets be down to a 20mm rotor and the parking brake hat is only 5mm bigger. Down side is 8x6.5 and the hub register is too small.

20mm rotor will allow use of a rear caliper from a trailblazer, which is a single 48mm piston versus my current dual 44mm.

Attachments

I've been putting off replacing my torque boxes for long enough. Between the rust and repeatedly dropping the jeep on body mounted sliders, they are looking pretty rough. Drivers side is the worst, so I'll start there and see how far I get before good weather.

When I bought the Jeep back in 2004 it had a salvage title and had been repaired by a local body shop. The left rear corner was crunched and spliced back together. Apparently when he did the seam across the rear floor pan he just overlapped them 1" and tacked the top of the joint together. Without any seam sealer, it collected dirt/salt and rust. Plan is to deal with that at the same time.

When I bought the Jeep back in 2004 it had a salvage title and had been repaired by a local body shop. The left rear corner was crunched and spliced back together. Apparently when he did the seam across the rear floor pan he just overlapped them 1" and tacked the top of the joint together. Without any seam sealer, it collected dirt/salt and rust. Plan is to deal with that at the same time.