Etatum

Well-known member

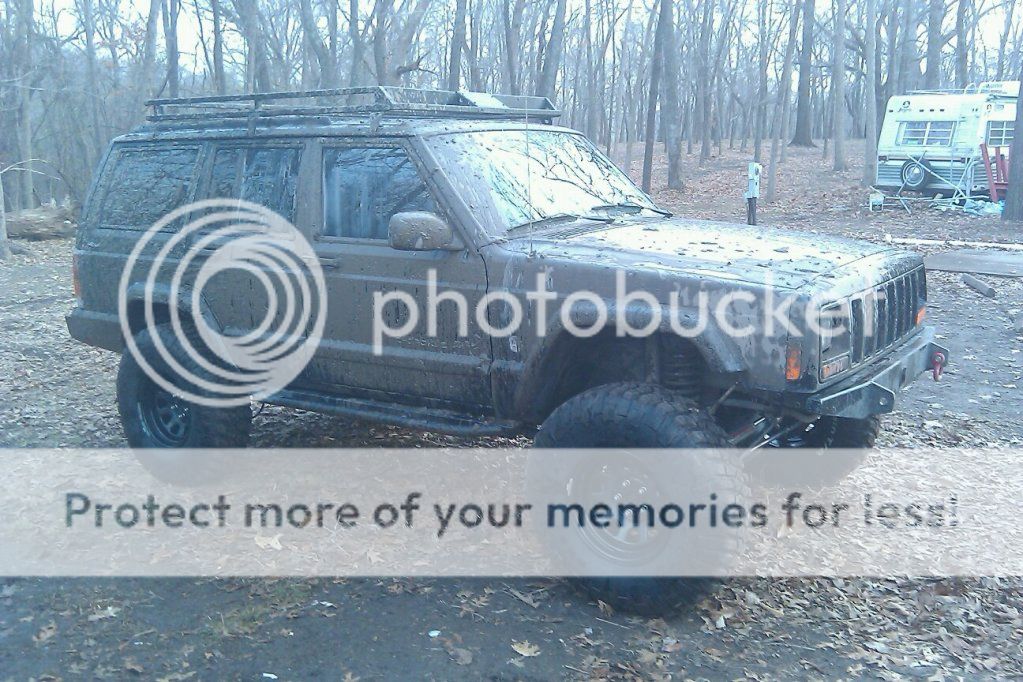

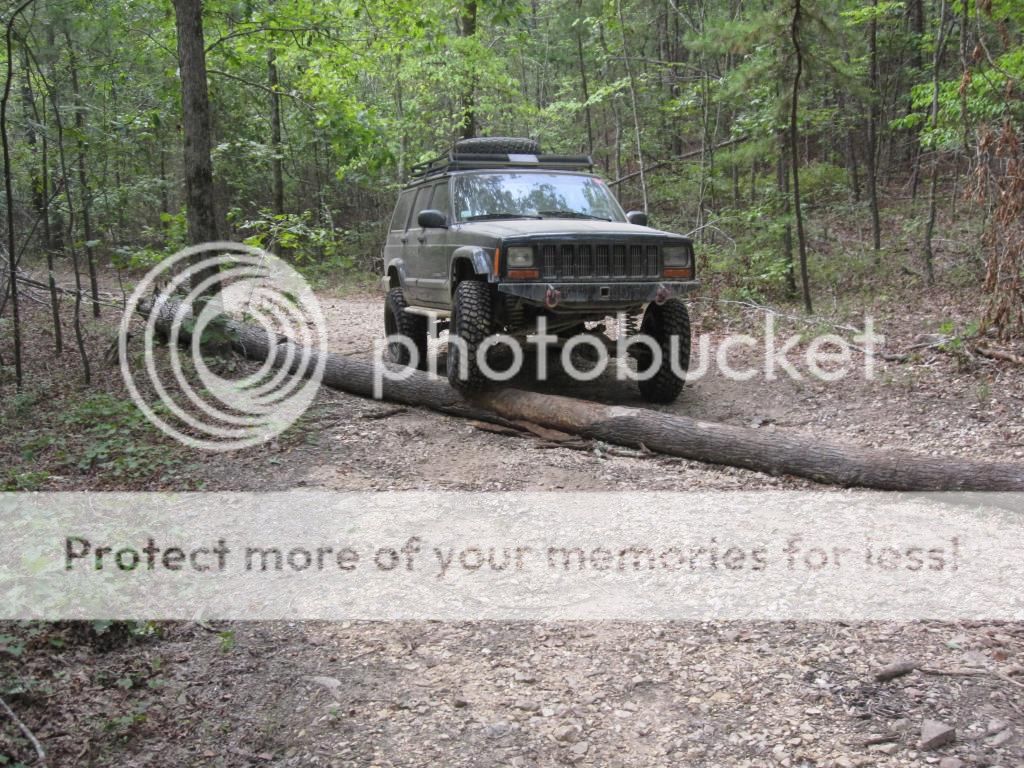

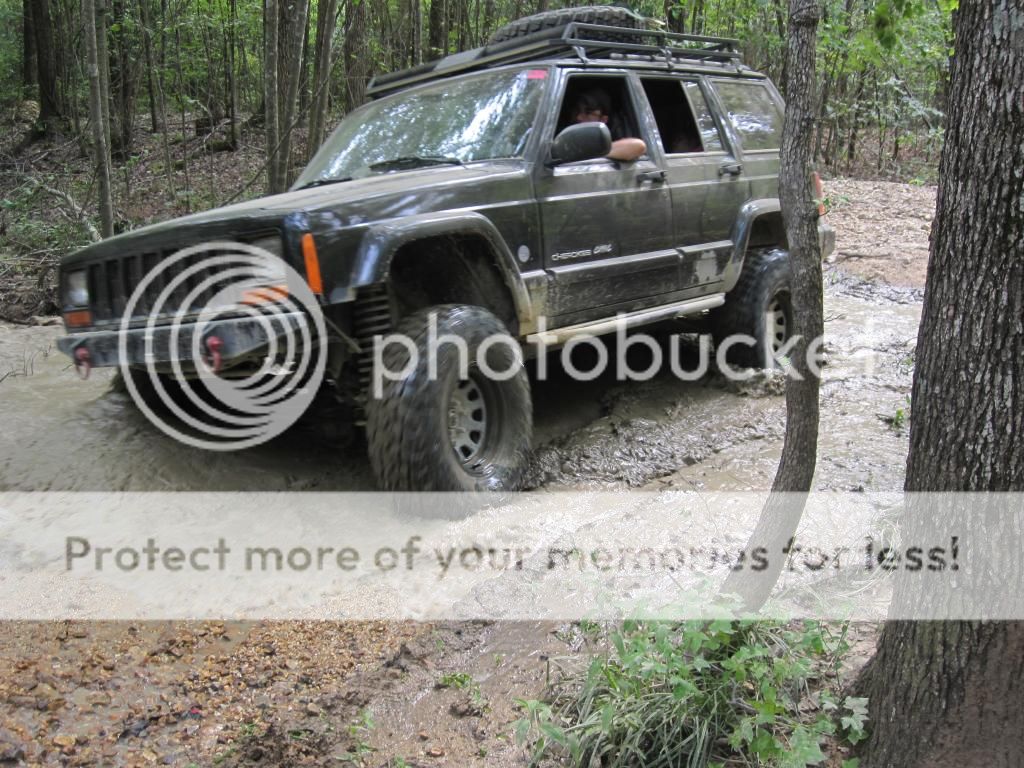

Project Heavy Metal.

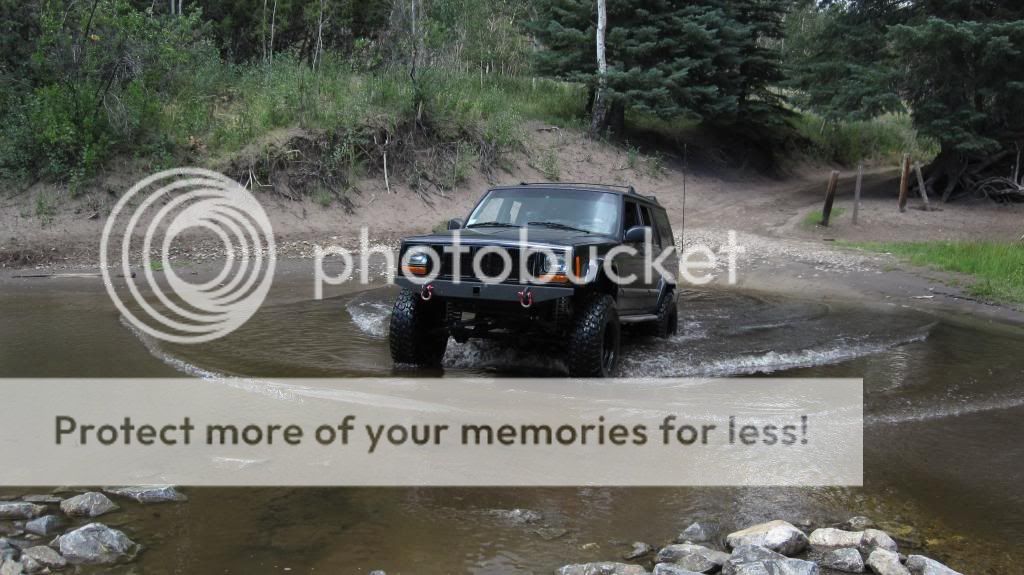

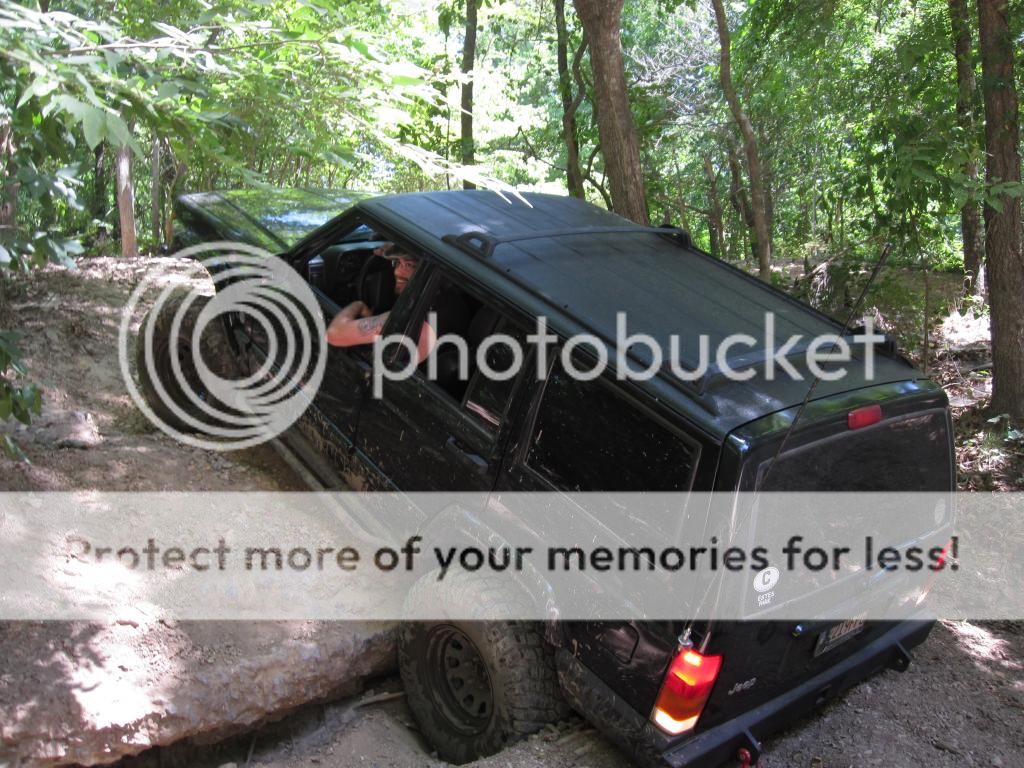

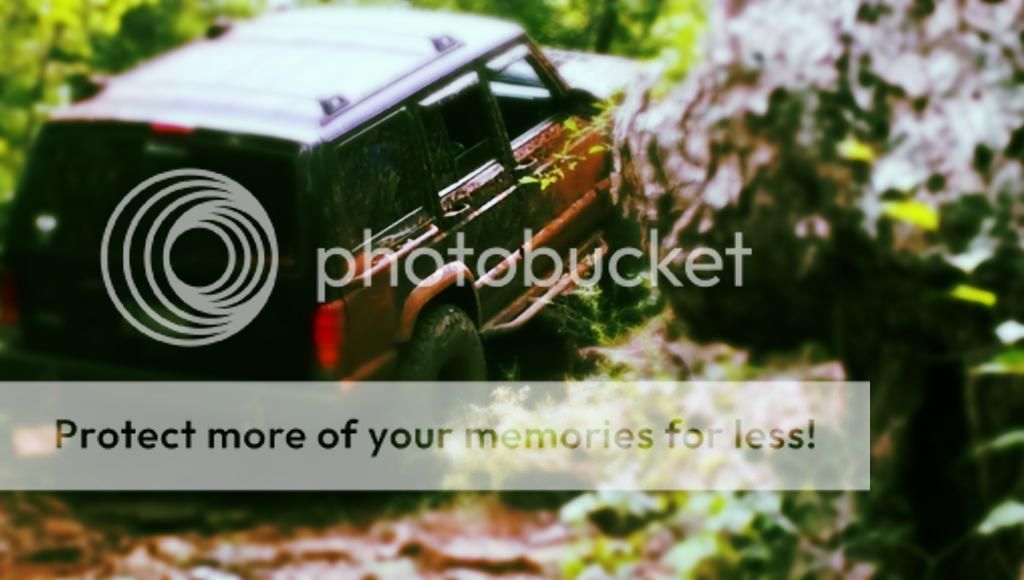

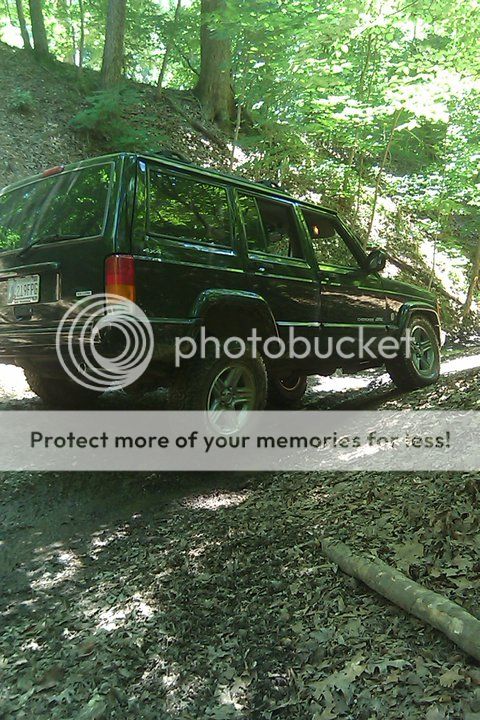

The purpose of this build thread is to document my family?s life experiences, including everything good and bad, that come from owning and modifying a 2000 Jeep Cherokee Sport that we have affectionately named Digger.

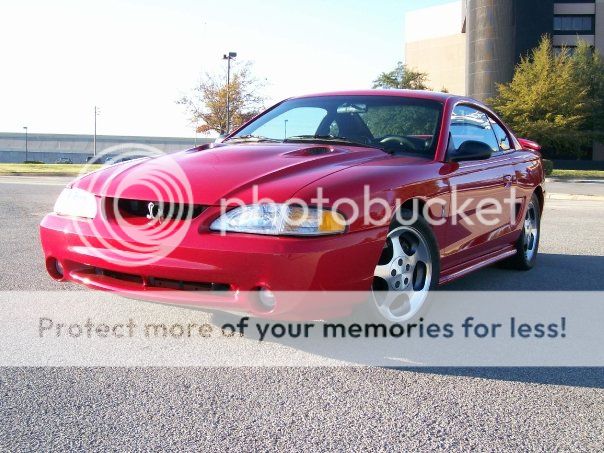

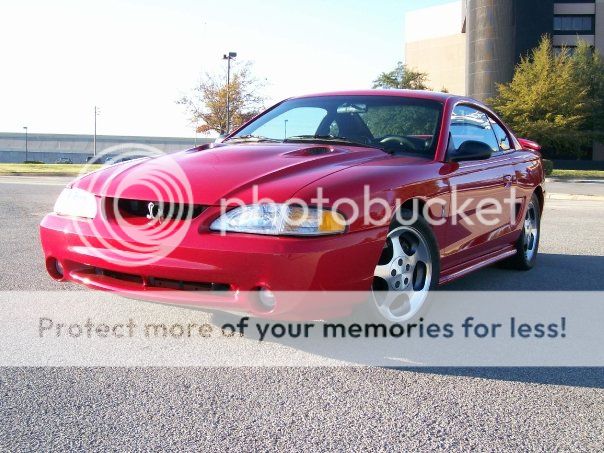

Digger came into our lives due to a series of unforeseen events, that changed both my view of priorities as well as how I see an automobile. I am the proud father of two beautiful daughters, the second of which came into the world a bit sooner than expected. This situation lead to a bit of a financial pinch at the time, ultimately ending my fast car addiction. I was always interested in cars, especially ones that were fast and loud.

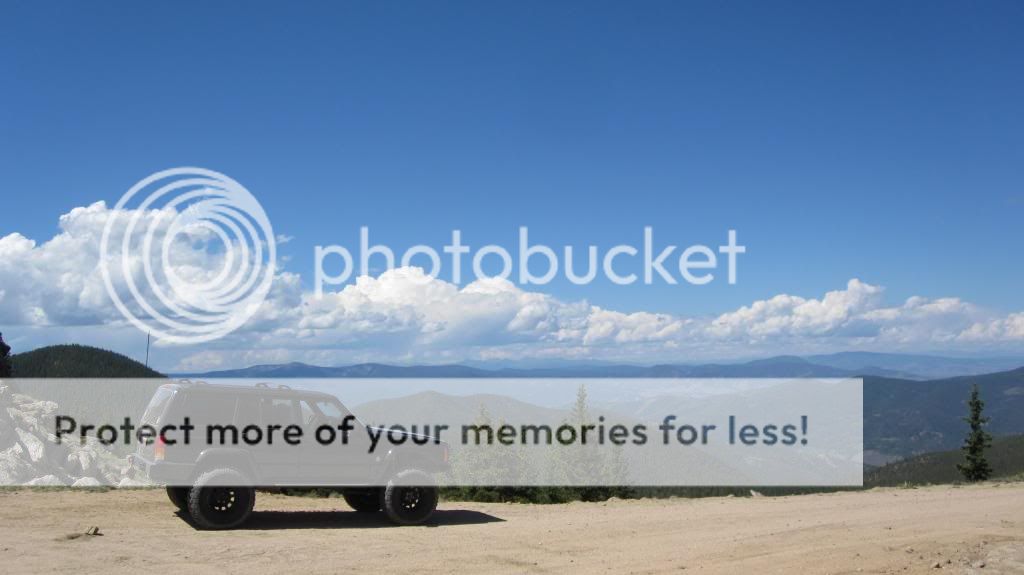

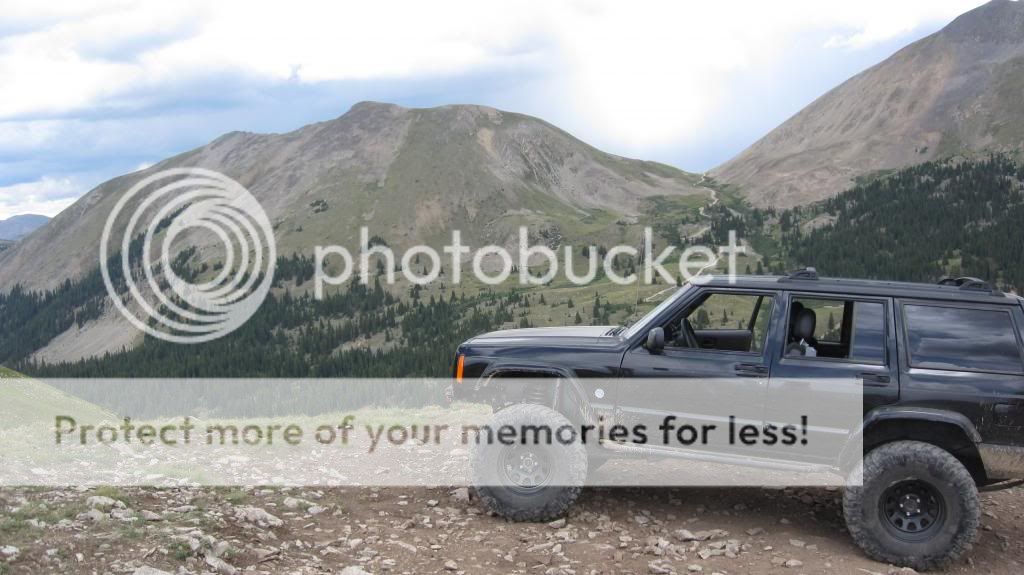

Unfortunately , sick babies and fast cars don?t mix well and I needed something a bit more practical. Growing up in Colorado, I spent plenty of time in the mountains in the back of a pickup bouncing up old logging roads and mountain passes. Knowing and believing fully that eventually the little one would get bigger and healthier, I decided that simple offroading was something the whole family could enjoy. The short search began for something practical, cheap, readily available and with the potential to become something more when the times got easier. A Jeep Cherokee seemed to fit the bill, and within a couple days I found what I was looking for.

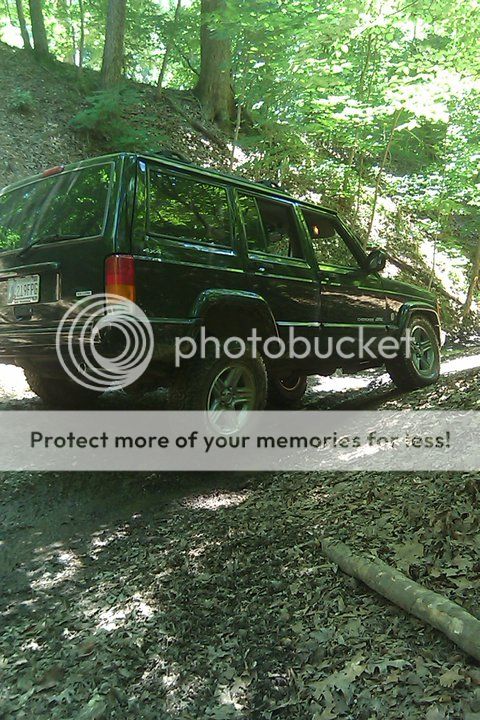

Digger was a straight, clean and bone stock Cherokee, with zero rust and about 75k miles. The A/C didn?t work, and there was oil coming from everywhere. It?s hot here in OK and this gave the perfect excuse to knock $1,000 off of the asking price. After a short time at the little car lot, I drove Digger home and proceeded to fix the aforementioned issues.

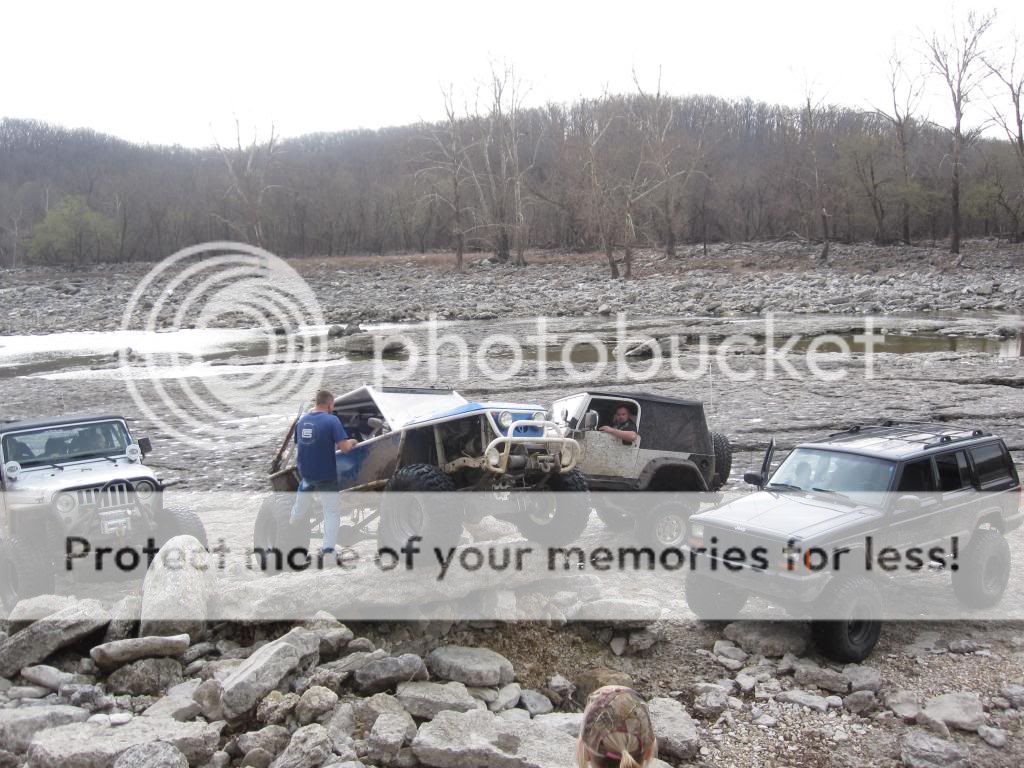

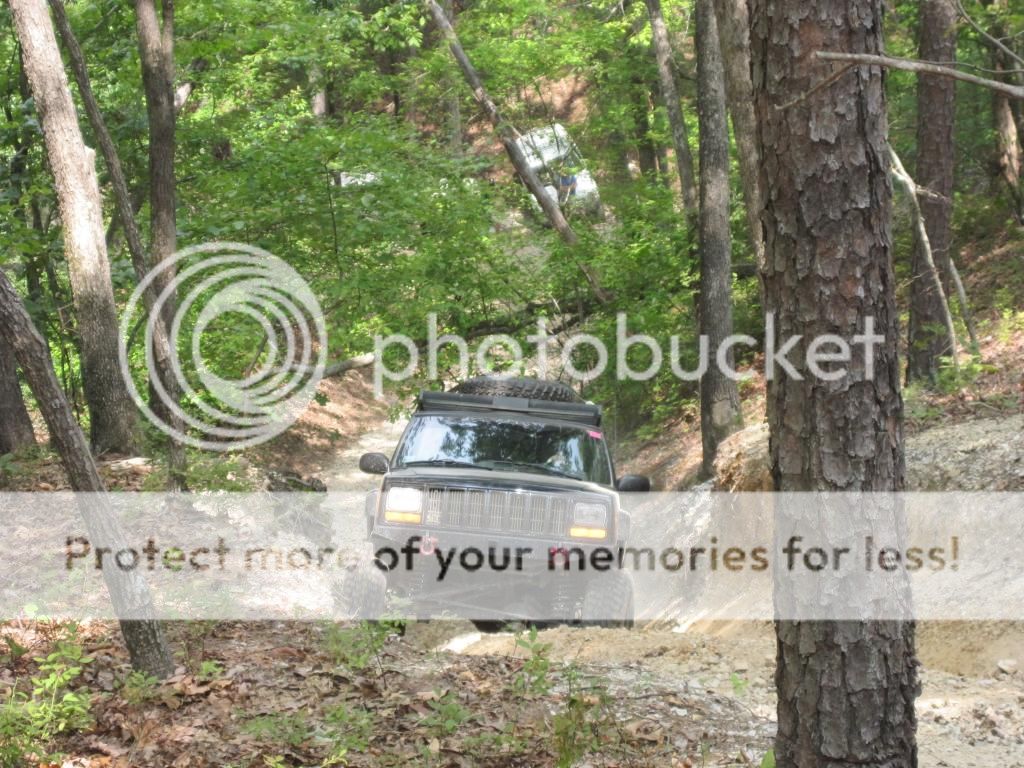

It was within a couple of weeks of ownership, my wife took the little ones to go see family in Colorado. I had burned through all of my vacation, so that left me home alone with my new 4x4. Time to go wheeling!

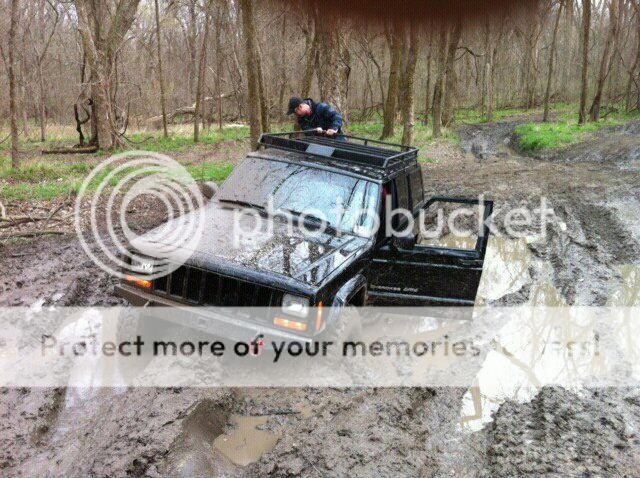

I quickly learned that mud holes in OK are not to be trusted, and took my new jeep (still with paper tag) belly deep in some nasty stuff, hydrolocked the engine and soaked the carpet.

OOPS

(Insert pic of flooded jeep here.)

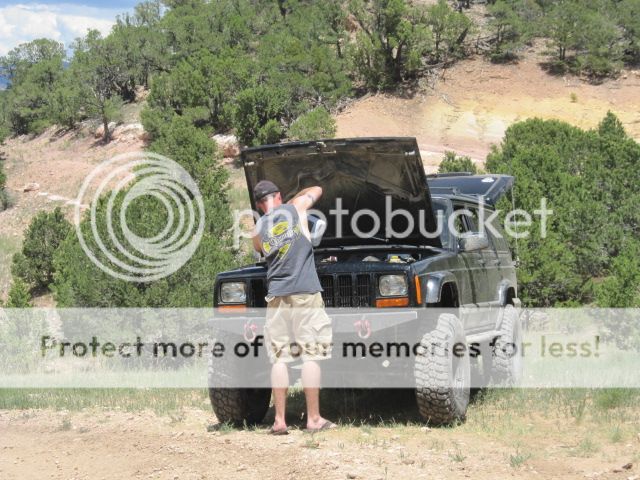

Thankfully we weren?t out there alone, and within a couple hours got the motor dried out and fired up with some ether. A short 30 min drive home with the floorboards soaked, lead to a completely gutted interior and some power washer action. The mass backing on the carpet was ruined, and promptly removed. By the end of the weekend the carpet was dried, reinstalled and clean. I replaced the o2 sensors that fried from being submerged while hot, flushed all the fluids in the driveline and threw in some new plugs. I bought a cheap scanner to clear the faults, and was good to go before momma got home!! This made it easier to break the news that my soccer dad jeep was no longer just that!

I continued to drive Digger stock for another year and a half wheeling when time allowed.

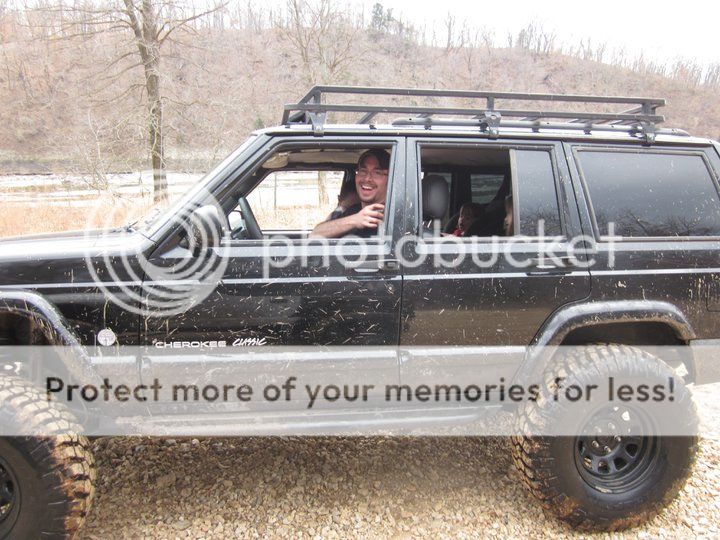

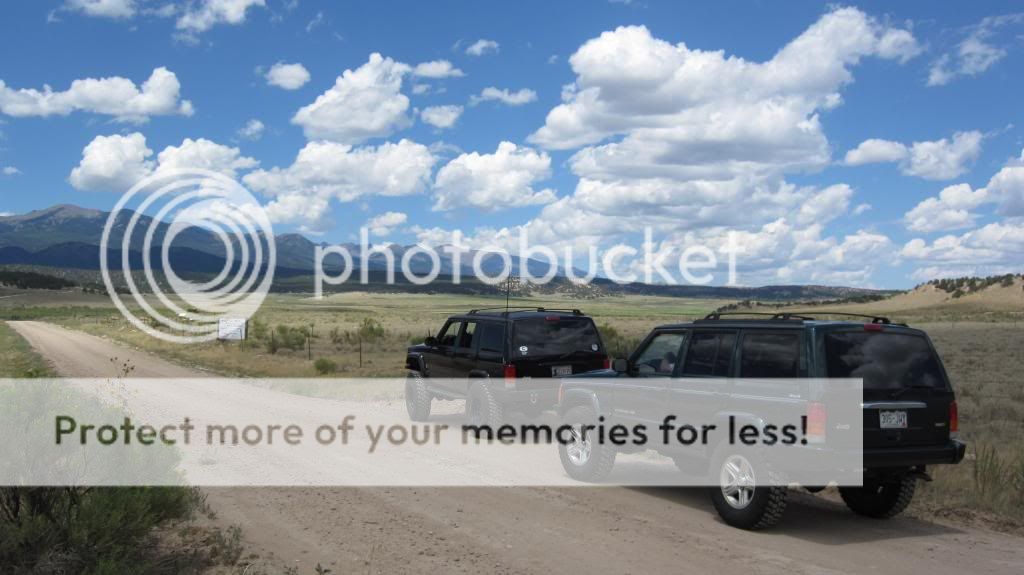

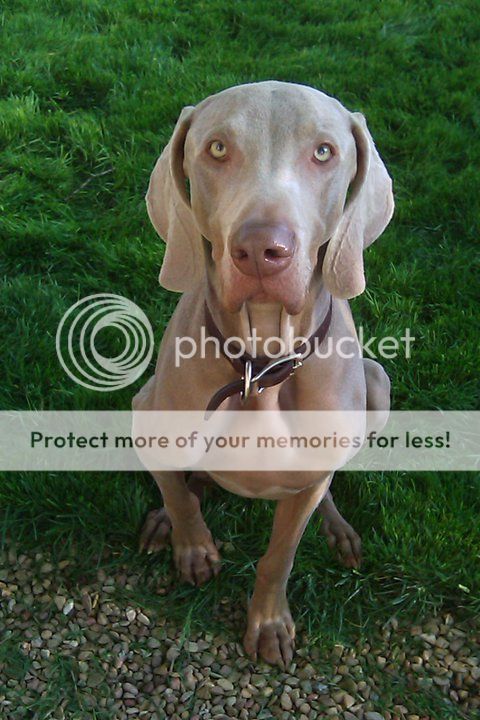

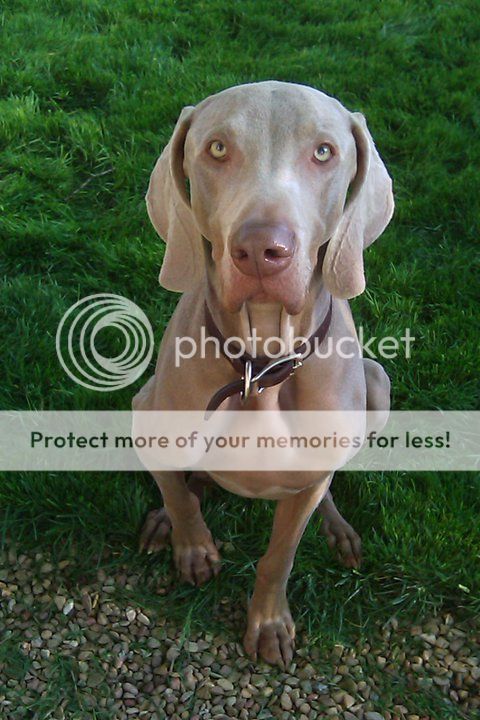

In preparation for a trip back home to Colorado for some camping and light trailriding, I needed some more space for luggage and the what not. With a big dog ?

and four humans, the back of Digger was way overpacked. Store bought roof racks were all way too expensive, and too small for my tastes so I figured I would just make one.

This is when the modding began.I bought a cheap welding helmet and busted out the harbor freight welder, and slowly but surely tried to teach myself to weld. The end product actually ended up decent, and stayed on top of Digger for a few years.

After flooding the interior and removing the sound deadening, the amount of road noise was beyond what I wanted to tolerate so, in with some sound deadening!

The purpose of this build thread is to document my family?s life experiences, including everything good and bad, that come from owning and modifying a 2000 Jeep Cherokee Sport that we have affectionately named Digger.

Digger came into our lives due to a series of unforeseen events, that changed both my view of priorities as well as how I see an automobile. I am the proud father of two beautiful daughters, the second of which came into the world a bit sooner than expected. This situation lead to a bit of a financial pinch at the time, ultimately ending my fast car addiction. I was always interested in cars, especially ones that were fast and loud.

Unfortunately , sick babies and fast cars don?t mix well and I needed something a bit more practical. Growing up in Colorado, I spent plenty of time in the mountains in the back of a pickup bouncing up old logging roads and mountain passes. Knowing and believing fully that eventually the little one would get bigger and healthier, I decided that simple offroading was something the whole family could enjoy. The short search began for something practical, cheap, readily available and with the potential to become something more when the times got easier. A Jeep Cherokee seemed to fit the bill, and within a couple days I found what I was looking for.

Digger was a straight, clean and bone stock Cherokee, with zero rust and about 75k miles. The A/C didn?t work, and there was oil coming from everywhere. It?s hot here in OK and this gave the perfect excuse to knock $1,000 off of the asking price. After a short time at the little car lot, I drove Digger home and proceeded to fix the aforementioned issues.

It was within a couple of weeks of ownership, my wife took the little ones to go see family in Colorado. I had burned through all of my vacation, so that left me home alone with my new 4x4. Time to go wheeling!

I quickly learned that mud holes in OK are not to be trusted, and took my new jeep (still with paper tag) belly deep in some nasty stuff, hydrolocked the engine and soaked the carpet.

OOPS

(Insert pic of flooded jeep here.)

Thankfully we weren?t out there alone, and within a couple hours got the motor dried out and fired up with some ether. A short 30 min drive home with the floorboards soaked, lead to a completely gutted interior and some power washer action. The mass backing on the carpet was ruined, and promptly removed. By the end of the weekend the carpet was dried, reinstalled and clean. I replaced the o2 sensors that fried from being submerged while hot, flushed all the fluids in the driveline and threw in some new plugs. I bought a cheap scanner to clear the faults, and was good to go before momma got home!! This made it easier to break the news that my soccer dad jeep was no longer just that!

I continued to drive Digger stock for another year and a half wheeling when time allowed.

In preparation for a trip back home to Colorado for some camping and light trailriding, I needed some more space for luggage and the what not. With a big dog ?

and four humans, the back of Digger was way overpacked. Store bought roof racks were all way too expensive, and too small for my tastes so I figured I would just make one.

This is when the modding began.I bought a cheap welding helmet and busted out the harbor freight welder, and slowly but surely tried to teach myself to weld. The end product actually ended up decent, and stayed on top of Digger for a few years.

After flooding the interior and removing the sound deadening, the amount of road noise was beyond what I wanted to tolerate so, in with some sound deadening!